Rebar is usually a simple steel bar or block that is well-liked in reinforced concrete and bolstered masonry buildings. These rebars will often be made from carbon metal which allow it to be recounted as reinforcing metal or maybe reinforcement. Underneath Structural BIM Services Rebar detailing could be a self-discipline of producing fabrication or shop drawings of steel reinforcement for the design course of action. The location fabrication drawings that come about being produced depending on style and design drawings for reinforcing metal are Rebar In depth drawings. Engineers and Architects make style and design drawings to provide about the desired strengths determined by the rebar detailing that offers diameter, bar shapes, quantities, length of bars to aid your web site for keeping away from delays and wastage therefore dashing the whole building process.

Every single rebar is specific symbolizing a shape, length, and diameter dependant on the requirements within the design drawing. The Rebar placement is then demonstrated at length which implies the concrete go over, specific spot, and Unique method of placement if essential. The rebar specifics and bar bending schedules might have bar diameter, bar notation, the amount of bars, bodyweight from your bars, and duration of Just about every bar along with mentioning the complete excess weight in your whole list of bars put inside drawing. In the preparing of rebar details, the stock lengths of bars are trapped in look at so that There is no wastage Using the materials.

Rebar Detailing and Reinforcement concrete detailing is often modeled and coded in 3-dimension whilst employing 3D Modelling technology like BIM Modelling Products and services. The specialised rebar detailing software program like Rebar CAD and AutoCAD employed for this goal may well enable just about every member in the structural engineering to prepare designs, doc, monitor, and General control.

Obtaining recognized the fundamental idea of rebar detailing a little of structural BIM modeling, let us to attempt to comprehend the importance of it in the entire construction approach is. Some on the good reasons are:

Importance of Rebar detailing in Structural BIM Modeling

Although second drawings and bending schedules usually are developed and offered, the 3D design can also be issued to all or any the team associates beginning from the consulting engineer and contractor departments right down to the steel fixers that transpire for being in the stroll-out on-internet site. The mix of such two turn out to be Primarily perfect for web page staff where site restrictions or congestion of reinforcements remain unknown until you'll find reinforcement and fixation on-web-site. For each and every bar, the actual position of repairing is proven In the 3D design and any hindrances or obstructions.

Making detailing reinforcements in 3D more than the 2D system is not only speedier but modeling rebar while in the 3-dimensional natural environment will help eliminate clashes. Although modeling one can maybe visualize if any in the bars tend never to fix in a resolved location, thereby identify these clashes inside of rebar drawings. There exists perhaps the facility to examine the reinforcement in comprehensive element just like a exact depth representation just before it getting staying ordered through the fabricator and sophisticated cages are assembled off-web site.

When There is certainly the appropriate rebar detailing Answer offered, a good and accurate reinforcement product can be achieved by importing structural calculations while in the structural analysis system. With Automation included the variations can be reflected in the 3D rebar detailing along with essential updates to drawings and schedules swiftly when improvements are made elsewhere not like obtaining to complete guide adjustments to second sections and views.

As an alternative to based on handbook enter from paper schedules, the rebar fabricator can extract knowledge immediately from the product in the direction of the equipment. The concrete pours may be nicely-outlined while in the product in conjunction with other details like portions and volumes To make sure extra precision in taking care of materials deliveries. This enables better control and end in fewer wastage and minimize in overall costs.

Getting 3D specific electronic styles will not likely prohibit the gain to some one-phase like that with the engineering and detailing phase but can be made use of during the phases. Getting reinforcement thoroughly modeled in 3D, the contractor is confident that it'll effortlessly slot in parts in the event the time comes so that it is mounted on-web-site. The data from the product might be employed within the area to permit contractors to conduct a product-based layout by using robotic whole station equipment along with monitoring rebar and elements and figuring website out exactly where and when They are going to be necessary.

Fixers existing on-web page can glance during the product natural environment to the rebar detailing to precisely recognize its application, i.e. specifically what exactly is expected when and the place as an alternative to according to their interpretation of common 2D drawings.

The structural engineers can surely as well as far more swiftly create design and style stories, schedules, and drawings during the 3D product as as opposed with 2nd types, thus enhancing layout efficiency. There is extra precision on rate projection Based on the rebar quantities generated with the 3D product as is also extra responsible than the 2nd drawing acquire-offs. Not just this the quantities are absolutely traceable, enabling comparisons and checks remaining done simply.

Using these causes, we could conclude that Rebar Detailing a self-control of Structural BIM Modelling Expert services is a person from the crucial requirements for your All round achievement of your undertaking everyday living cycle. To summarize, acquiring Rebar Detailing the rebar contractor can give full attention to manufacturing rebars the place there are going to be no need to estimate reinforcement necessities for procurements at the Website resulting from economical 3D versions. The product will depict the benefits of anchors and laps inside the drawings therefore guaranteeing structure adequacy as well as decreasing wastage. The general squander and time delays are decreased at the positioning simply because all of the shape drawings are generally obtainable. Dependant on these records the bars can be easily fabricated determined by the styles and quantity of bars essential.

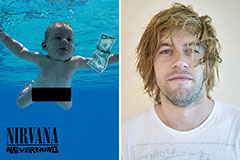

Jonathan Taylor Thomas Then & Now!

Jonathan Taylor Thomas Then & Now! Spencer Elden Then & Now!

Spencer Elden Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now!